Parabolic leaf springs are a vital component of any automotive suspension system, providing an effective means for carrying high payloads while still ensuring that the occupants ride comfortably. These progress of HUAYU rear leaf spring have long been developed, with their layout and compound increasing regularly to be able to cater for the needs of current running transportation.

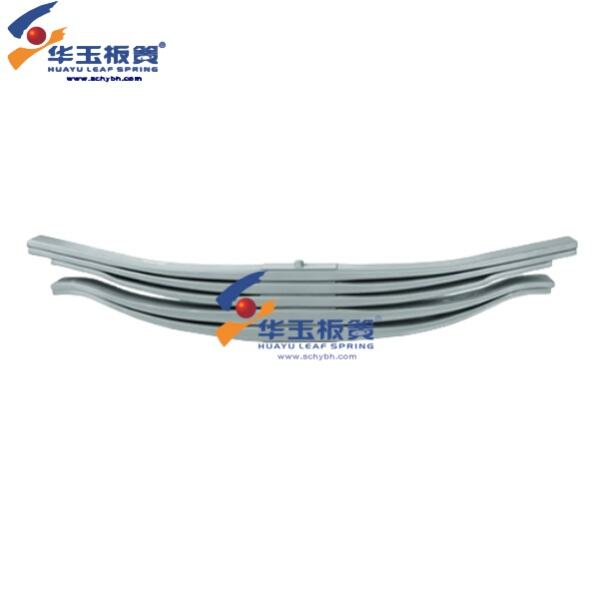

Due to high load carrying capability and reduced deflection, parabolic leaf springs are in use for heavy duty applications. Parabolic leaf springs are different from conventional multi-leaf spring, improving ride comfort, handling ability and durability.

Parabolic leaf springs have an asset in the way they share weight better along their length. This provides less strain on individual components which means they will last longer and be more robust. Additionally, the HUAYU rear leaf spring distinctive form and design also helps give an extra layer of smoothness that gives them a highly desirable line for taxing operations.

Various factors determine the choice between traditional leaf springs and HUAYU leaf spring helper. Parabolic leaf springs are becoming more popular because of their superior handling and durability, however for most applications traditional style leaf’s will still be satisfactory.

Parabolic leaf springs may provide a more advantageous suspension systems if you prioritize high ride comfort, better handling and long service life. Still, it all comes down to your particular needs and necessities of course.

For parabolic leaf springs to have a long life and deliver optimum performance, they need regular maintenance. Take note of these helpful tips for HUAYU leaf spring helper.

· Regularly inspect your parabolic leaf springs for cracks or rust as these signs of wear and tear can have a detrimental effect on its performance.

· Ensure your parabolic leaf springs are always kept completely clean from dirt, debris and moisture which could result in corrosion as well as other damages.

· Consistently use a top-tier leaf spring lubricant for your parabolic leaf springs in order to reach the best level of performance.

· If you have not yet done so, a good position to start would be the high-quality parabolic leaf springs that will take care of improving handling and ride comfort (by bettering suspension components) as well durability.

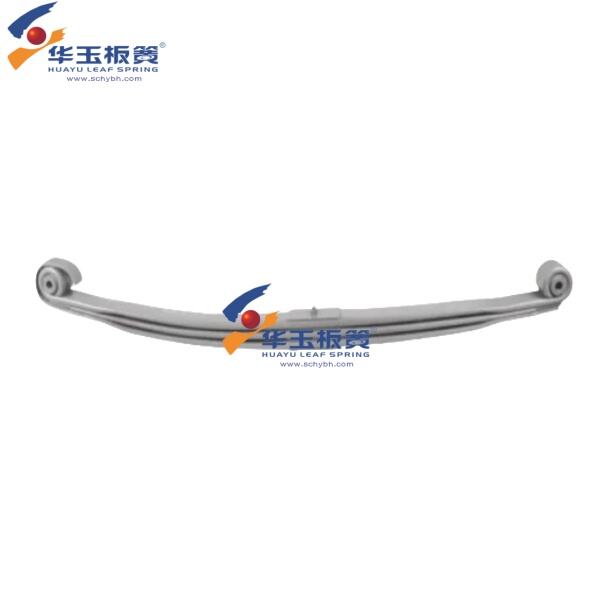

Parabolic leaf springs are named as such because of their curved or paraboloid shape which is a significant difference between ordinary leaf spring designs. This tapered construction gives it, even more, flexibility and durability, making for a distributed load over the length of the spring. This results in reduced stress on individual components, and ultimately greater system longevity and performance. The curved shape and "over under" design of HUAYU auto leaf springs also provide for a more comfortable ride, which is important in medium to heavy-duty applications.

Improving the Suspension of Your Ride with Quality Parabolic Leaf Springs

Parabolic leaf springs are a great replacement for those looking to upgrade their vehicle's suspension system. Brody begins by stating, "Our coil springs provide a smoother ride while handling better and having increased strength that is perfect for heavy-duty applications / pursuits. Parabolic leaf springs come in various types, so if you want your investment to last over time and provide the needed versatility be sure purchase a quality product matching your needs. Choose brands that use high-quality materials and strict quality controls for peak reliability, longevity, and an improved driving experience. Top of the line HUAYU auto leaf springs will make a world of difference to how your vehicle performs, lasts and drives -lifting your driving experience from good to great.

We have more than 30 years expertise in the manufacturing of various Parabolic leaf spring springs and air springs. No matter if you require leaf springs for heavy-duty vehicles and trailers, light trucks, or even heavy trucks You can find the perfect fit here.

Today, the company has a total annual production capacity of around 30000 tons Parabolic leaf spring ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds promptly within 72 hours to address every customer's needs.

We're committed to providing outstanding service to each customer We are committed to continuously Parabolic leaf spring our technology and getting certifications such as ISO14001 and IATF16949 and ISO 45001.

Our springs are Parabolic leaf spring of high-quality raw materials and auxiliary materials. We use modern production techniques, extensive techniques for inspection, and strict quality control to ensure they exceed the expectations of our clients in terms of performance, size and appearance.

ONLINE

ONLINE