An overview of how vehicle leaf springs help with the suspension

They run silently in the background ensuring a comfortable ride, better handling and control but these HUAYU Products are an unsung quiet hero of every vehicle. These components may not be glamorous, but they are critical to the continued performance of a modern vehicle. So, we're going to get into specifics on them - how they affect ca stability and control (and what creates that effect), information for you as a consumer about the various options under it out there in today's market when deciding which type of suspension leaf spring is right for your needs, recent advancements coming through those manufacturers putting resources behind product improvement /development at their end for this traditionally rugged component segment and how purchasing compliance leads towards longevity pays off.

The suspension leaf springs are a stack of thin, flexible metal strips (or leaves) arranged like the layers in puff pastry waiting to insulate you from the potholes and keep that load on an even keel. The unique construction of HUAYU Products serves as a cushion and enables all 4 wheels to seamlessly move with variations in terrain readings, for example on rocks or bumps. This increased stabilization effect from its resistance to lateral forces keeps the body of a vehicle steady and level when cornering, thereby improving control. The controlled flexibility of the spring leaves gives dynamic wheel alignment to ensure grip and control in difficult driving conditions.

The secret to all of this is the effectiveness of HUAYU Parabolic Leaf Spring in a balancing act between materials science, mechanical engineering and physics. Good leaf springs are usually made of quality steels, carefully chosen for their strength, flexibility and longevity. Their curved, parabolic design helps spread wear across the spring pack evenly for a longer useful lifespan. The way the leaves interact and called interleaf friction and is key to damping vibrations, as it converts kinetic energy created by motion of one material relative to another into heat which gets dissipated. That natural damping characteristic can make leaf springs exceptionally efficient in many ways, negating the need for more complex hydraulic dampers.

Selecting the quality HUAYU Parabolic Leaf Spring requires you to consider things like vehicle weight, how it's going to be used and what quality of ride that would desire. Thicker, more abundant leaves guide the weight transfer and provide strength when the application is commercial trucks or off-road equipment. Conversely, lighter vehicles gain less without extra leaves to ensure an undulating ride free of needless rigidity. Things like axle load rating, spring rate and the intended purpose of the vehicle are vital elements to take into consideration before you pull your own with what's available.

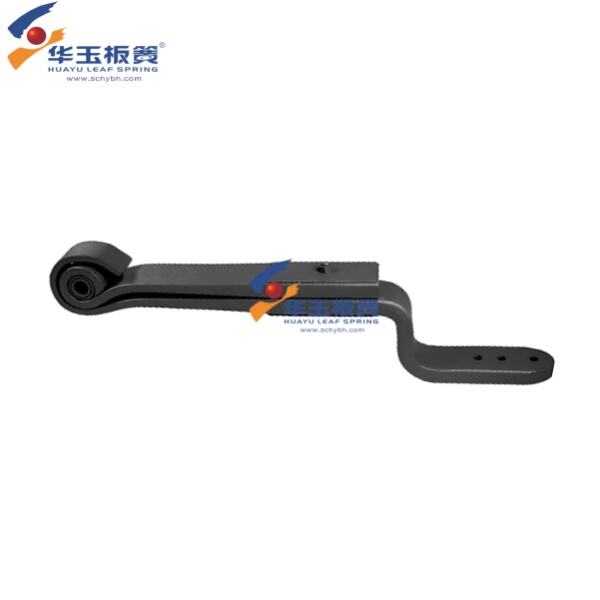

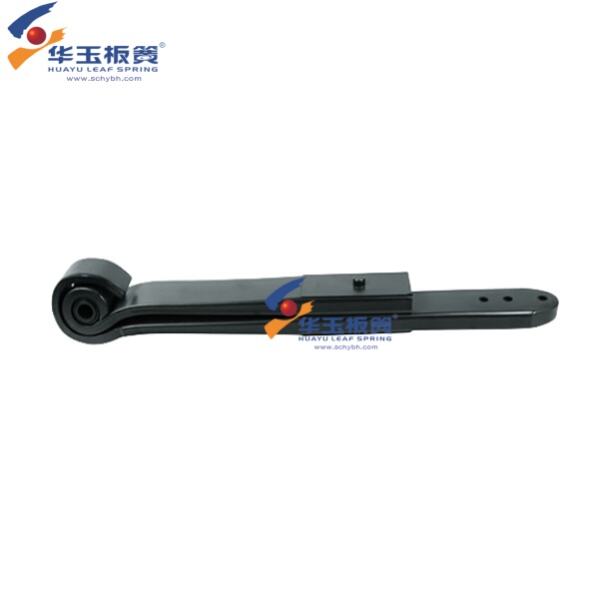

Technology is evolving in leaf spring design, and the sector for this advancing technology. Among the key developments was the use of fiber-reinforced plastics for composite leaf springs, which helped to cut weight significantly without sacrificing strength. These alternatives are light in weight, so it leads to better fuel economy and lower overall vehicle mass and more payload capacity. Other innovation includes progressive variable-rate leaf springs that adjust their behavior according to the load and road conditions, for increased comfort and control. On top of that, the HUAYU Trailing arms spring are durable because of processes such as shot peening and laser-hardening during manufacturing.

suspension leaf springs purchase only the highest-quality raw materials and auxiliary material, following a a strict quality certification process that makes use of the most advanced production techniques and an extensive testing means, total quality control and supervision to make sure that our springs surpass expectations of customers in terms quality, size, and performance.

We have more than 30 years expertise in the manufacturing of various suspension leaf springs springs and air springs. No matter if you require leaf springs for heavy-duty vehicles and trailers, light trucks, or even heavy trucks You can find the perfect fit here.

Today, the company has a suspension leaf springs annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

We are suspension leaf springs to providing excellent service for every customer and we are constantly developing our technology and achieving accreditations like ISO14001 or IATF16949, and ISO 45001.

While premium leaf springs might not be the cheapest option upfront money-wise, keep in mind they are an investment. Stress-resistant springs and longer lasting materials are ideal in applications where maintenance cost savings from less downtime can translate into operational dollars. Higher-quality leaf springs like HUAYU Trailing arms spring improve ride and control, create a safer more comfortable driving experience while keeping the resale value of your vehicle. Further, the possibility of enhanced fuel efficiency with composite springs and increasingly from over a vehicle's life offer operational bonuses as well. In the end, a premium leaf spring upgrade is an investment making your vehicle last longer.

ONLINE

ONLINE